Browse by topic

Franchising

Learn about why Tommy's Express offers the best franchise experience for car wash operators.

Equipment

Our equipment lineup sets you up for success inside and outside the wash tunnel.

Detergents

Learn the ins and outs of car wash chemistry so that you consistently produce a clean, shiny car.

Marketing

Best practices for signage, advertising, SEO, and all other marketing for your car wash.

Operations

Learn how to keep your wash running consistently and efficiently.

Buildings

Our unique building design makes it easy and fun for your customers to get a great car wash.

Recent posts

Molded Mat Washing Made Easy: Introducing the Tommy Molded Mat Washer

Are your customers struggling to clean their dirty molded floor mats? We have the solution. For years, car owners have grappled with the tedious task of...

TCWS is Bringing the Future of Car Washing to The Car Wash Show 2024

Get ready for The Car Wash Show 2024 from May 13-15 in Nashville, TN with Tommy Car Wash Systems (TCWS). Whether you are a new investor, car wash...

Wash Club: A Perfect Solution for Car Wash Businesses of All Sizes

Are you looking to streamline your car wash operations and provide a superior experience for your customers? Look no further than Wash Club's membership...

Streamline Your Backroom Operations with Our Water Treatment Center

Does your car wash backroom feel cluttered and overwhelming? Do you struggle with frequent leaks, time-consuming maintenance, and a complex water...

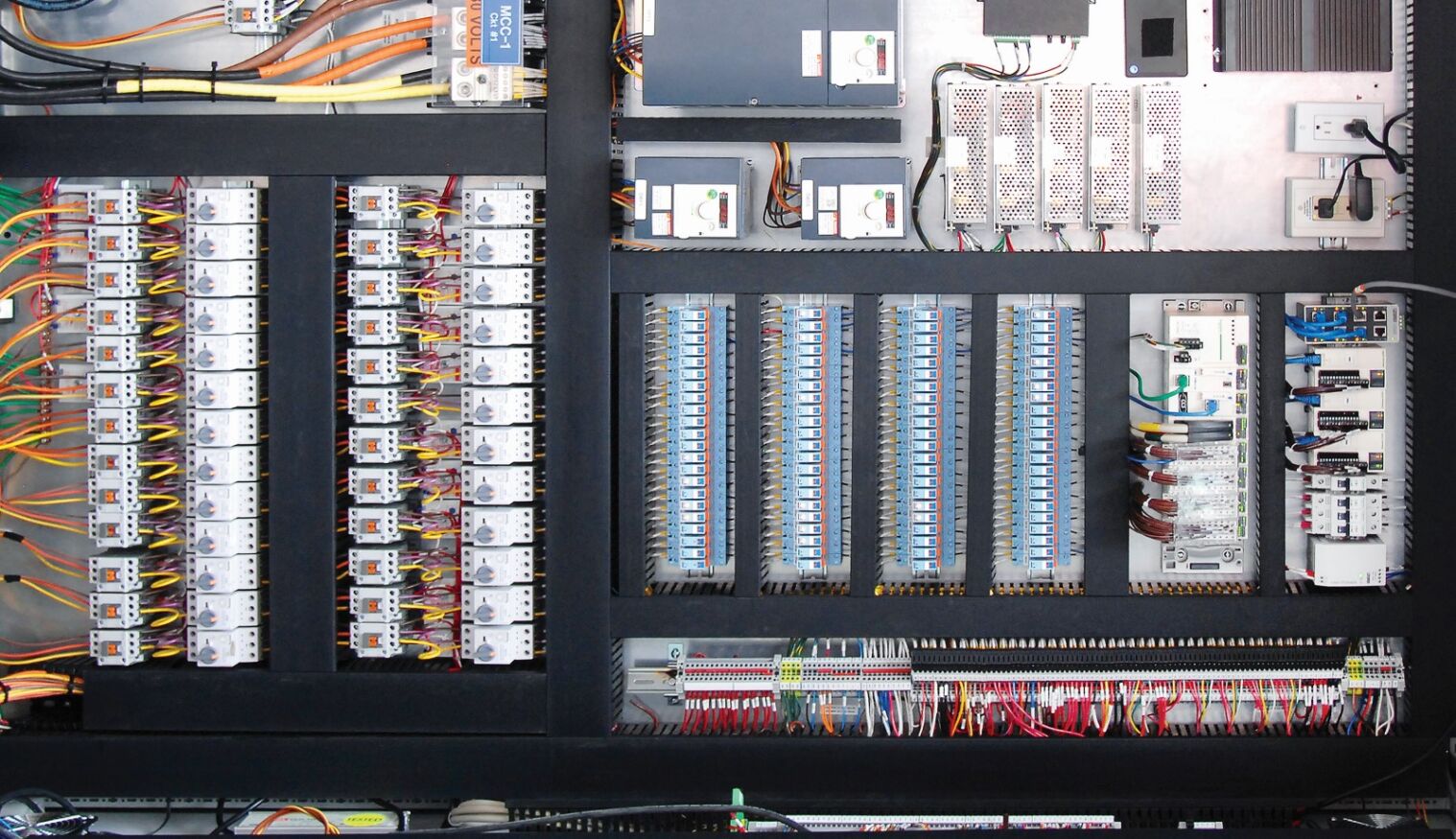

Take Control of Your Car Wash Success with Guardian Wash Command™

In the competitive world of car washes, efficiency and reliability are crucial to delivering an excellent experience. That's where Guardian Control...

Offer Robust Self-Serve Interior Cleaning with Tommy Vacuums

Tommy Car Wash Systems takes self-serve interior cleaning to a whole new level. Our vacuums boast numerous impressive features that make it easy for...